By Larry Busby, Technical Services Manager at APsystems USA

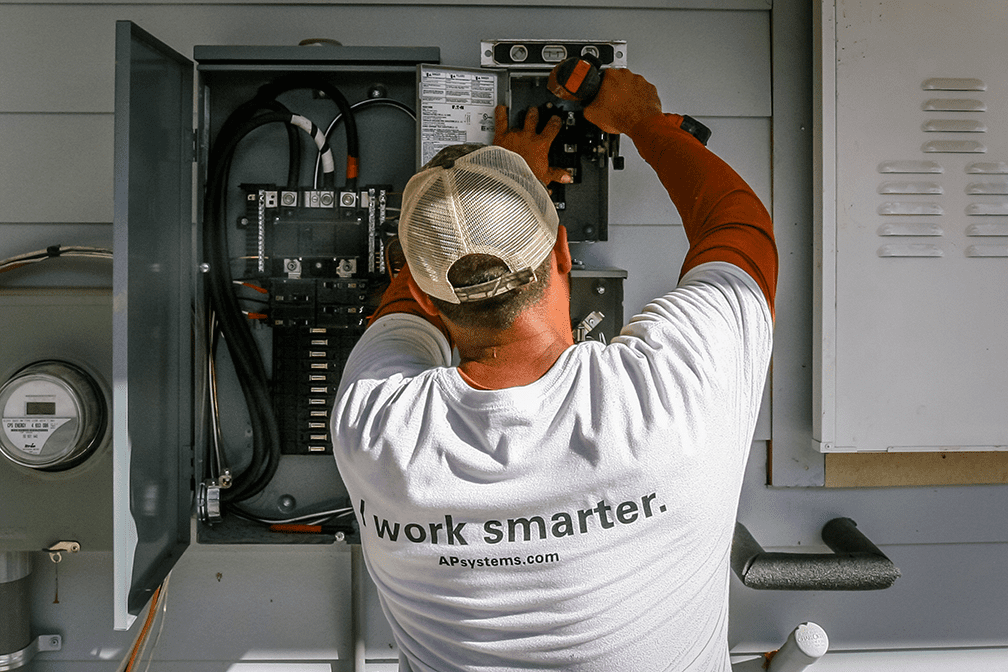

For a PV installer, there’s nothing worse than having to return to a jobsite. Except, of course, having to do it more than once. We’ve all heard the expression “work smarter, not harder,” but you would be surprised how often solar installers get in a truck and roll out to a jobsite to adjust or repair something that probably could have been fixed remotely back at HQ. Many software-savvy solar installers are boning up on best-practices to better utilize the systems and information already available to them—most of it right at their fingertips—to save both time and money.

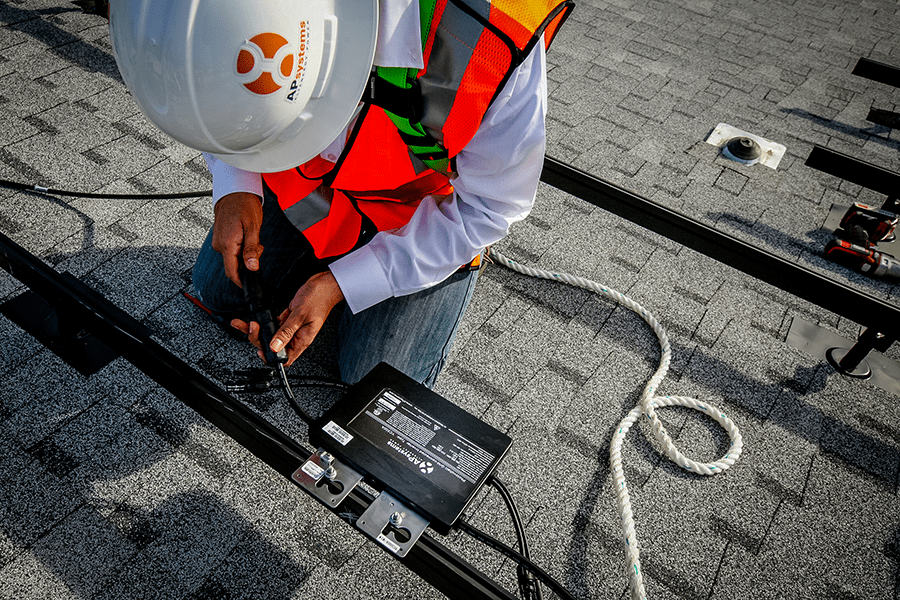

For solar arrays, the most critical software typically lies within the power conversion devices, gateways and interconnected online monitoring platform provided by the inverter manufacturer. The online platform not only monitors the performance of the system, but also tracks a profusion of data points simultaneously and stores that information in the cloud. By checking certain performance specs, settings, activity and historical data, installers can quickly troubleshoot and fix common hitches or, at worst, narrow down the problem that’s plaguing a PV system.

Every inverter monitoring interface is a little different, but much of the information and tools available are typically the same. With an MLPE system like microinverters, you’re able to drill down to the PV panel level to see what each module is producing at any given time. When troubleshooting a system issue, or perhaps if you see a PV panel which is reporting low or zero watts, first try rebooting the system remotely if your monitoring platform offers that capability. With some systems, a reboot may help the interface identify the issue or it might reset the array to its default parameters in case an unusual grid event threw a monkey wrench at it. It could also spur the system to begin downloading recent updates which may have stalled when the system encountered the issue. You may even consider rebooting more than once.

If you’re still troubleshooting the issue, check the DC side of your system. For a microinverter system, you want to be sure each inverter is reporting at its minimal operating range (such as 16V) incoming DC from the panel. Next, check your AC output. If your system shows it registering 0V or 120V, the inverter may not be sensing the grid or enough volts from the grid to register as a 240V grid connection. Without an identified grid connection, the inverter will not convert energy, so if you see this as an issue with multiple sequential inverters, it could be a cable or connector problem. If it applies to the entire string or array, the problem could be a loose wire in the junction box, or a tripped or off breaker.

With a low wattage problem, you can drill down to the panel level online and check the voltage. If it’s registering under its minimal operating range, it’s likely a panel problem and not the inverter. You may still have to visit the site, but at least you know what you’re replacing and exactly where it is on the array which saves you time troubleshooting. When you hit the site, unplug the suspect panel from the inverter and take a live load DC voltage and current reading. If your panel is reading below its minimum startup voltage and 0 current, then the panel is the culprit and needs replacing.

Also, don’t underestimate the value of historical data. Looking back over a system’s history—especially that of a single panel—may allow you to identify recurring issues that seem to affect that particular panel. Perhaps a chimney shadow hits the panel at the same time each day. You can look back through the production history to see if it occurs often, or if you have multiple installations in a particular area, you can check each of those when you see unusual grid activity to see if and how it may be affecting your other sites.

Understanding what the site metrics are telling you will give you better insight into what’s happening at a job site. Learning what you can do to troubleshoot an issue online can not only save you a truck roll, but also significantly reduce your time identifying the problem if you do have to drive to the site. Most importantly, if you do need to hit the job site, remember that safety is paramount and to always turn off the AC before doing any work on the roof.

Vegas, Here We Come!July 22, 2025 - 11:40 pm

Vegas, Here We Come!July 22, 2025 - 11:40 pm Meet Solar PupAugust 7, 2025 - 5:57 am

Meet Solar PupAugust 7, 2025 - 5:57 am APsystems Featured in Solar Builder: Leading the Charge on AI in SolarAugust 7, 2025 - 6:21 am

APsystems Featured in Solar Builder: Leading the Charge on AI in SolarAugust 7, 2025 - 6:21 am TEDDY Talks Takes Scottsdale: Two New Episodes Live!August 7, 2025 - 5:53 am

TEDDY Talks Takes Scottsdale: Two New Episodes Live!August 7, 2025 - 5:53 am Review APsystems & Win a $50 Starbucks Card!August 4, 2025 - 2:35 am

Review APsystems & Win a $50 Starbucks Card!August 4, 2025 - 2:35 am

The 5-minute Solar Installation

/in General News, Video/by APsystems TeamA complete 6.93kW solar installation in under 5 minutes? That’s right … thanks to the magic of video editing, and APystems microinverters!

Our friends at NextGen Energy have posted a great new video that compresses a whole 24-module rooftop project into an exciting short feature. And with their multi-module, plug-n-power design, APsystems YC500 microinverters helped the NextGen team get the job done fast.

Sure, it took a little longer than 5 minutes in real time … but the APsystems microinverter installation was fast and efficient. Less time on the job site means big savings for installers and customers alike … and that’s a wrap!

APsystems microinverters installed in northernmost grid-tied solar project

/in Case Studies, General News/by APsystems TeamAPsystems 3-phase microinverters now power the northernmost grid-tied solar installation in the Americas – the Community Hall at Pond Inlet, Nunavut, latitude 72N.

Vancouver Renewable Energy (VREC) powered up the 590kW system in Canada’s newest and northernmost province in September.

The 9.3kW community system features 32 SolarWorld 290-watt mono-crystalline modules and eight APsystems YC1000 true 3-phase microinverters.

In just three weeks the PV system had produced 590kWh of power, saving hundreds of dollars on the municipal power bill for the remote, 1,500-person hamlet. The community otherwise relies on a diesel “tank farm” and generator plant for its power needs – an expensive proposition now helped by clean, renewable solar and APsystems microinverter technology.

The new array will be paired with a mural celebrating light, both from the sun and from qulliqs, traditional Inuit lamps that use animal fat for fuel, according to the Vancouver Renewable Energy blog.

Read the whole story here.

APsystems offers installers microinverter training in Escondido, CA

/in Events, General News, Trainings/by APsystems TeamAPsystems and UMA Solar are offering 2 in-depth installation and setup training classes for CA solar installers. Don’t miss this opportunity to learn how to simplify PV system installation and save money with the industry-leading APsystems microinverter line.

You’ll also earn 2 NABCEP recurring education hours for attending a class! Free lunch provided. Fill out the form below to register.

Both classes are invited to Lunch & Learn with Neurio!

DATE/TIME/LOCATION:

Date: November 8th

Times:

9:30 – 11:30(this class is now full)1:30 – 3:30 (Available)

Address: 236 N. Hale Ave., Escondido, CA 92029

WHAT YOU’ll LEARN:

What is a Microinverter?

/in General News, Video/by APsystems TeamMicroinverters are a popular choice for residential and commercial solar installations. They inherently meet NEC 2017 requirements for module-level shutdown, increase system efficiency and performance, and help with shading issues. Learn more about how microinverters convert DC to AC power right at the panel level in this video.

World’s Most Advanced Solar Microinverter NOW SHIPPING!

/in General News, Press Releases/by APsystems TeamFOR IMMEDIATE RELEASE

NOW SHIPPING

APsystems Unveils World’s Most Advanced Solar Microinverter

/in General News, Press Releases/by APsystems TeamFOR IMMEDIATE RELEASE

LAS VEGAS – September 10, 2017 – APsystems introduces the YC600, a dual-module, utility-interactive microinverter with Reactive Power Control (RPC) technology and Rule 21 grid support functionality at Solar Power International in Las Vegas, NV.

The first of its kind, the YC600 was designed to accommodate today’s high output PV panels, offer enhanced capability and meet the latest grid compliance standards, including UL 1741 SA requirements for California Rule 21 as well as voltage and frequency ride through and RPC for European and Australian DER requirements.

Offering an unprecedented 300VA peak output power per channel, the YC600 works with 60 and 72-cell PV modules and offers dual, independent MPPT per panel. The unit operates within a wider MPPT voltage range than competing brands for a greater energy harvest and boasts a durable, NEMA 6/IP67, powder-coated aluminum enclosure, bucking today’s trend of plastic casings.

The YC600 builds on the successful APsystems line of multi-module microinverters, simplifying installation and reducing logistics costs. The unit features both integrated ground and DC connectors for fast, hassle-free installation and maintains inherent compliance to NEC 690.12 Rapid Shutdown code requirements. An integrated ZigBee antenna offers broadband communication over a mesh network for fast, accurate data monitoring.

“The demands on today’s power conversion systems require that manufacturers not only bring cutting-edge concepts into existence, but also include the complex capabilities of successful previous generations, all while accommodating both current and new compliance standards,” said Dr. Yuhao Luo, APsystems’ chief technology officer. “The YC600 includes dozens of new and advanced features and functions that outclass competing products. And then we added free monitoring.”

The groundbreaking new microinverter will debut at Solar Power International, being held in Las Vegas, Nevada, September 11-13, booth #1745. The product is now available in Australia and Asia-Pacific markets and will soon launch in the U.S. market mid-Q4 and EMEA market late Q4 of this year.

APsystems to Unveil World’s Most Advanced Solar Microinverter at Solar Power International

/in General News, Press Releases/by APsystems TeamFOR IMMEDIATE RELEASE

SEATTLE, Wa.; LYON, France; JIAXING, China – September 5, 2017 – APsystems will unveil the YC600, a dual-module, smart grid and Rule 21 compliant microinverter at the Solar Power International trade show in Las Vegas. A groundbreaking design in microinverter technology, the YC600 will offer the highest peak output power, faster transmission speed and more modules allowed per string than comparable microinverters. A wider MPPT voltage range will result in a greater energy harvest for homeowners.

The first of its kind, the YC600 is designed to accommodate today’s high output PV panels, offer enhanced capability and meet the latest grid compliance standards while providing an unprecedented level of power with dual, independent MPPT per channel. The unit also builds on the successful APsystems line of multi-module microinverters, simplifying installation and reducing logistics costs.

The new microinverter will debut at the APsystems booth #1745 September 11-13 at SPI.

APsystems to debut groundbreaking YC600 microinverter at SPI 2017

/in Events, General News/by APsystems TeamAPsystems will unveil the YC600, a dual-module, smart grid and Rule 21 compliant microinverter at the Solar Power International trade show in Las Vegas. A groundbreaking design in microinverter technology, the YC600 will offer the highest peak output power, faster transmission speed and more modules allowed per string than comparable microinverters. Additionally, a wider MPPT voltage range will result in a greater energy harvest for homeowners.

The first of its kind, the YC600 is designed to accommodate today’s high output PV panels, offer enhanced capability and meet the latest grid compliance standards while providing an unprecedented level of power with dual, independent MPPT per channel. The unit also builds on the successful APsystems line of multi-module microinverters, simplifying installation and reducing logistics costs.

The new microinverter will debut at the APsystems booth #1745 September 11-13 at SPI.

Email sales.usa@APsystems.com to set up a meeting during the convention or find out more about APsystems microinverter products.

Smart software for fewer truck rolls

/in Article, Case Studies, General News/by APsystems TeamBy Larry Busby, Technical Services Manager at APsystems USA

For a PV installer, there’s nothing worse than having to return to a jobsite. Except, of course, having to do it more than once. We’ve all heard the expression “work smarter, not harder,” but you would be surprised how often solar installers get in a truck and roll out to a jobsite to adjust or repair something that probably could have been fixed remotely back at HQ. Many software-savvy solar installers are boning up on best-practices to better utilize the systems and information already available to them—most of it right at their fingertips—to save both time and money.

For solar arrays, the most critical software typically lies within the power conversion devices, gateways and interconnected online monitoring platform provided by the inverter manufacturer. The online platform not only monitors the performance of the system, but also tracks a profusion of data points simultaneously and stores that information in the cloud. By checking certain performance specs, settings, activity and historical data, installers can quickly troubleshoot and fix common hitches or, at worst, narrow down the problem that’s plaguing a PV system.

Every inverter monitoring interface is a little different, but much of the information and tools available are typically the same. With an MLPE system like microinverters, you’re able to drill down to the PV panel level to see what each module is producing at any given time. When troubleshooting a system issue, or perhaps if you see a PV panel which is reporting low or zero watts, first try rebooting the system remotely if your monitoring platform offers that capability. With some systems, a reboot may help the interface identify the issue or it might reset the array to its default parameters in case an unusual grid event threw a monkey wrench at it. It could also spur the system to begin downloading recent updates which may have stalled when the system encountered the issue. You may even consider rebooting more than once.

If you’re still troubleshooting the issue, check the DC side of your system. For a microinverter system, you want to be sure each inverter is reporting at its minimal operating range (such as 16V) incoming DC from the panel. Next, check your AC output. If your system shows it registering 0V or 120V, the inverter may not be sensing the grid or enough volts from the grid to register as a 240V grid connection. Without an identified grid connection, the inverter will not convert energy, so if you see this as an issue with multiple sequential inverters, it could be a cable or connector problem. If it applies to the entire string or array, the problem could be a loose wire in the junction box, or a tripped or off breaker.

With a low wattage problem, you can drill down to the panel level online and check the voltage. If it’s registering under its minimal operating range, it’s likely a panel problem and not the inverter. You may still have to visit the site, but at least you know what you’re replacing and exactly where it is on the array which saves you time troubleshooting. When you hit the site, unplug the suspect panel from the inverter and take a live load DC voltage and current reading. If your panel is reading below its minimum startup voltage and 0 current, then the panel is the culprit and needs replacing.

Also, don’t underestimate the value of historical data. Looking back over a system’s history—especially that of a single panel—may allow you to identify recurring issues that seem to affect that particular panel. Perhaps a chimney shadow hits the panel at the same time each day. You can look back through the production history to see if it occurs often, or if you have multiple installations in a particular area, you can check each of those when you see unusual grid activity to see if and how it may be affecting your other sites.

Understanding what the site metrics are telling you will give you better insight into what’s happening at a job site. Learning what you can do to troubleshoot an issue online can not only save you a truck roll, but also significantly reduce your time identifying the problem if you do have to drive to the site. Most importantly, if you do need to hit the job site, remember that safety is paramount and to always turn off the AC before doing any work on the roof.

APsystems congratulates the Top 500 Solar Contractors of 2017

/in Events, General News, Trainings/by APsystems TeamSolar Power World’s 2017 Top Solar Contractors list is out, and APsystem solar partners are in the top ranks.

The annual list ranks solar installers and other contractors according to their influence in the U.S. solar industry. These leading firms are active in markets across the country, and SPW notes the cumulative installation numbers from the past year in all markets, services and states.

Congratulations to APsystems solar partners who made the list. Thank you for showing leadership across the industry and pointing the way to a clean energy future.

Find the entire list of Solar Power World’s 2017 Top 500 Solar Contractors online here