Apollo Solar’s Award-Winning Residential Carport Installation in Lanesville, IN

In the quiet countryside of Lanesville, Indiana, innovation meets everyday utility in a solar installation that’s as practical as it is powerful. Designed and installed by Apollo Solar, the 14.85kW system has been named the 2024 U.S. Residential Project of the Year in APsystems’ Installation Awards.

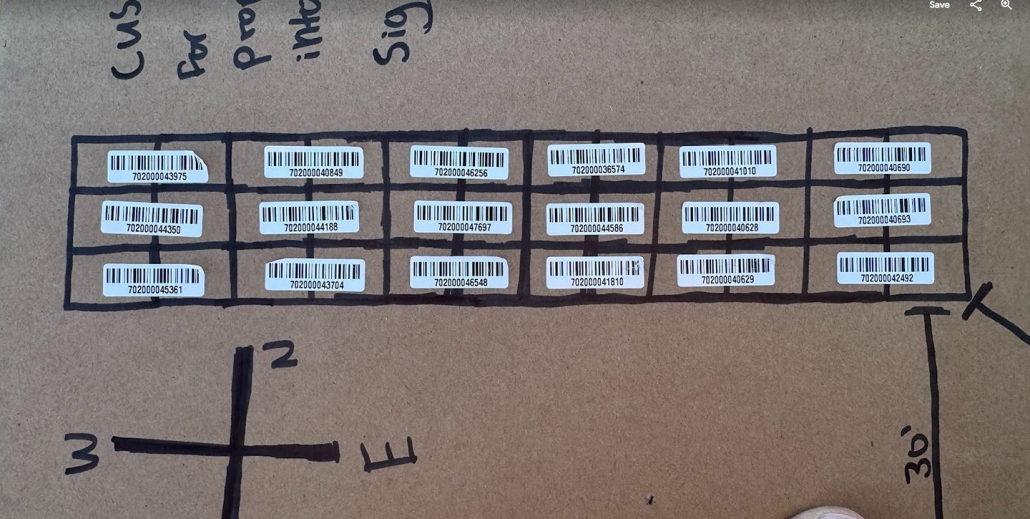

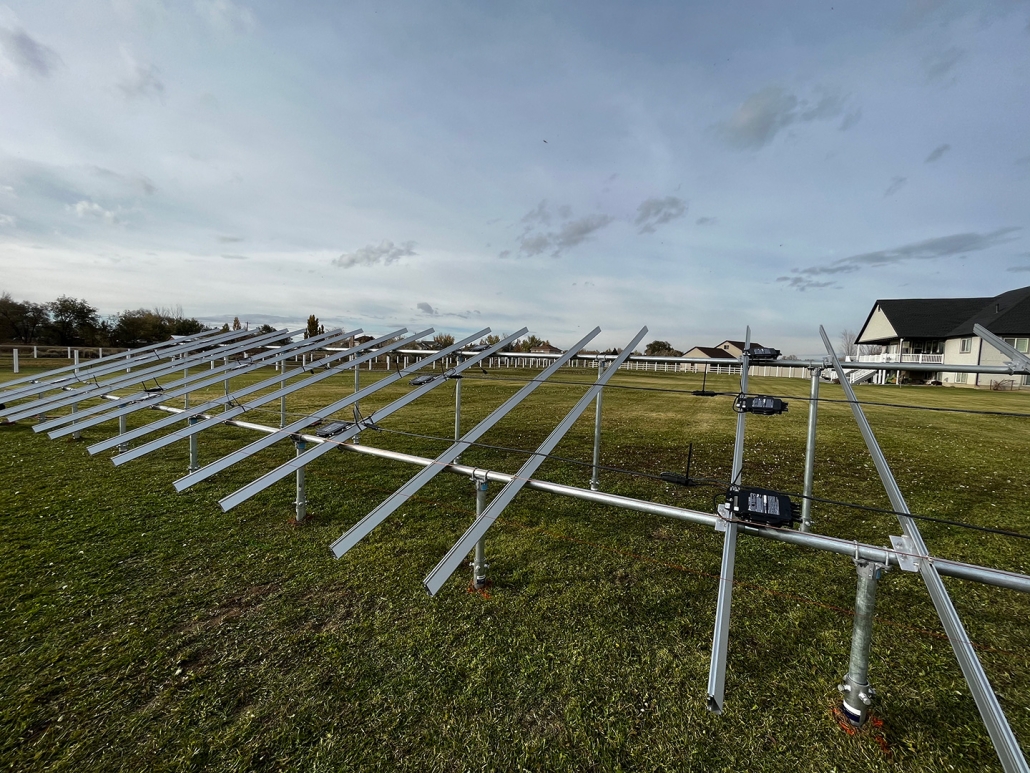

The award-winning project features a custom-built solar carport that delivers dual benefits: providing covered parking for the homeowners while generating enough clean energy to bring the household to net zero. With a commitment to solving multiple homeowner needs through one integrated solution, Apollo Solar has set a new bar for residential solar excellence.

“We’re always looking for ways to meet the unique needs of our clients,” said Christopher Robinson, Owner of Apollo Solar. “This install provided the perfect opportunity to combine form, function, and sustainability.”

A longtime believer in APsystems technology, Apollo Solar chose APsystems microinverters for this installation due to their reliability, performance, and flexibility. “APsystems is always our go-to,” Robinson explained. “Fewer points of failure, dependable performance, and user-friendly monitoring—it’s what every homeowner wants in a solar setup.”

The installation process was described as streamlined and consistent, thanks to the plug-and-play nature of APsystems’ microinverter lineup. The system’s flexible configuration made it an ideal match for a custom carport project, delivering seamless integration across panel orientations and conditions.

The installation process was described as streamlined and consistent, thanks to the plug-and-play nature of APsystems’ microinverter lineup. The system’s flexible configuration made it an ideal match for a custom carport project, delivering seamless integration across panel orientations and conditions.

End users have expressed high satisfaction, citing the simplicity of the monitoring platform and the peace of mind that comes with a trustworthy product. Even the city and utility inspectors were impressed—so much so that Apollo Solar was added to the area’s list of recommended installers.

For Apollo Solar, this project is more than a win—it’s a testament to what’s possible when design, purpose, and technology come together. With APsystems microinverters as a constant in their toolkit, Apollo continues to bring bold ideas to life—empowering homeowners with energy independence and smart solar design.

SEE OTHER WINNERS HERE