When uncertain times defy innovation, new opportunities shine brightly for a long time.

This year marks APsystems’ 10th anniversary. While the situation worldwide is facing unexpected challenges on many fronts during this very particular year 2020 with the Coronavirus pandemic, Dr Zhi Min Ling, co-founder and chairman of APsystems, shares his views on his entrepreneurial story with APsystems from its very beginning when the economic effects of the 2008 financial crisis were still strongly present to where APsystems is today, having become the #1 multi-module microinverter supplier in the world. It is as if challenging uncertainty could also be a key in building long-lasting opportunities.

2020 is the year of APsystems celebrating its 1st decade, how does it make you feel?

Fortunate, honored and grateful. It is a major milestone for the company, especially in this very fast-changing inverter industry which is at the crossroads of high-tech microelectronics, energy and environmentally-friendly building sectors. Staying alive is one thing but growing profitably when you need to heavily invest in R&D on one side, while keeping enough agility to adapt to an ever-changing emerging market on the other side, is another challenge. The fact that we have been growing for 10 years while reaching profitability every year since 2012, is primarily down to the hard work, determination and patience of the hundreds of talented and committed people who have joined and believed in this company over the years.

What encouraged you to set up APsystems? And how has the company evolved over the years?

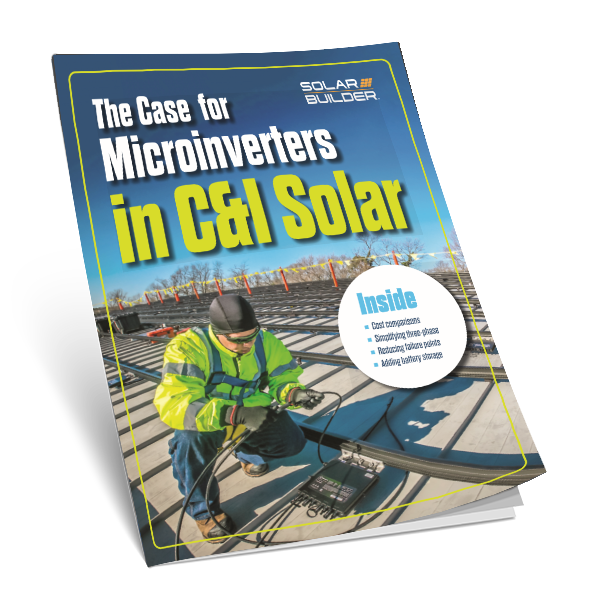

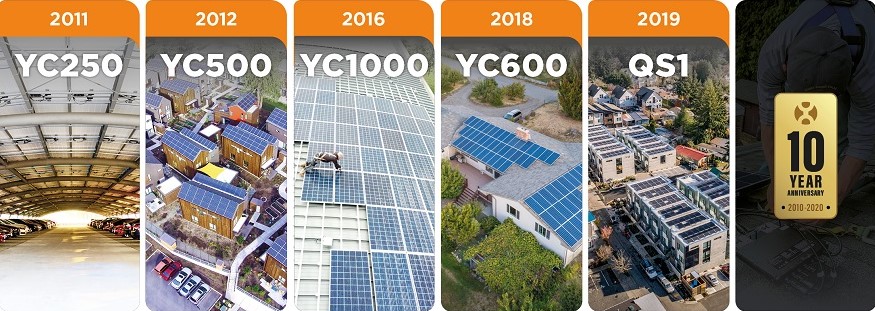

The company has changed dramatically for sure. We can look at the company’s development in two phases, I think. The foundation 2010 – 2012: it was the very beginning where every priority was focused on setting up our expertise in power electronics conversion designs to create a robust and cost-efficient microinverter solution. Within about two years, we managed to design, manufacture and launch our 1st single and duo microinverter products with the YC250 and YC500 which later became the best-selling duo microinverter worldwide. We set up our headquarters in Jiaxing, China, where we still manufacture our products thanks to the help of TDG group, our main shareholder and share our R&D department between Jiaxing and Cupertino….Then the 2nd phase was characterized by one obsession: how to make APsystems Grow Internationally with no compromise to profitability. Although we are still in this phase with constant profitability every year since 2012, I would say that over the past six years (2013-2019), and especially since Olivier Jacques joined the company in 2015, we have managed to structure ourselves by Business Units on all continents enabling us to serve our customers in more than 80 countries today.

What were the main challenges along the way?

It is quite fascinating to be able to be part of this solar revolution. Helping to make solar an affordable clean energy solution to everyone on this earth is inspiring but of course, the technological challenges are big. If you take communications for example, microinverters manage a considerable number of data points that need to be communicated back from the microinverters through the gateway and to the monitoring platform in the cloud. This means when systems like the YC1000, QS1 and YC600 apply remote firmware upgrades, this creates a demanding bidirectional data flow and traditional powerline communication isn’t going to cut it. This is the reason why we moved our portfolio to high-speed wireless Zigbee, which is up to three times faster than conventional powerline communication (PLC), creating a local 2.4GHz mesh network for fast and reliable data communication between the microinverters and the gateway.

Another constant challenge has been to adapt to increasingly complex market needs. The progressive integration of PV into the electricity networks has required Inverter manufacturers in many countries to release products capable of interacting in real-time with grid operators. Whether it is to adjust the PV production instantaneously, depending on the state of the network, or to prevent any electron from being sent back, performing such a functionality for the coming 20 years in a reliable manner with a product smaller than an A4 sheet and weighing 3kg average is a genuine achievement in technological integration, entailing very sophisticated R&D , manufacturing and testing capabilities.

How is the Pandemic situation affecting your activity?

When the COVID-19 first appeared in China at the beginning of the year, our activities were relatively spared since part of our production comes from outside China, even though a slowdown in manufacturing occurred during a period of about 1 month in the first quarter. The good news is that as we master the production infrastructure, we were able to quickly increase our production rate when the situation improved a few weeks later, ensuring a constant continuity of supply to all our customers and warehouse locations across the world.

Despite the inherent agility of our distributor partners and solar installers staying open and continuing their job as far as possible, we have inevitably been confronted by a slowdown in our sales activity worldwide this quarter. Uncertainty is the most difficult parameter to deal with when it lasts, it is the same for everyone as an individual but it is also a genuine opportunity to confront and challenge ourselves by overtaking obstacles with self-confidence. I strongly believe that the creativity and flexibility of our industry will rapidly lead to recovery during the 2nd half of this year.

What’s next for APsystems?

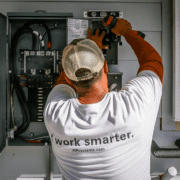

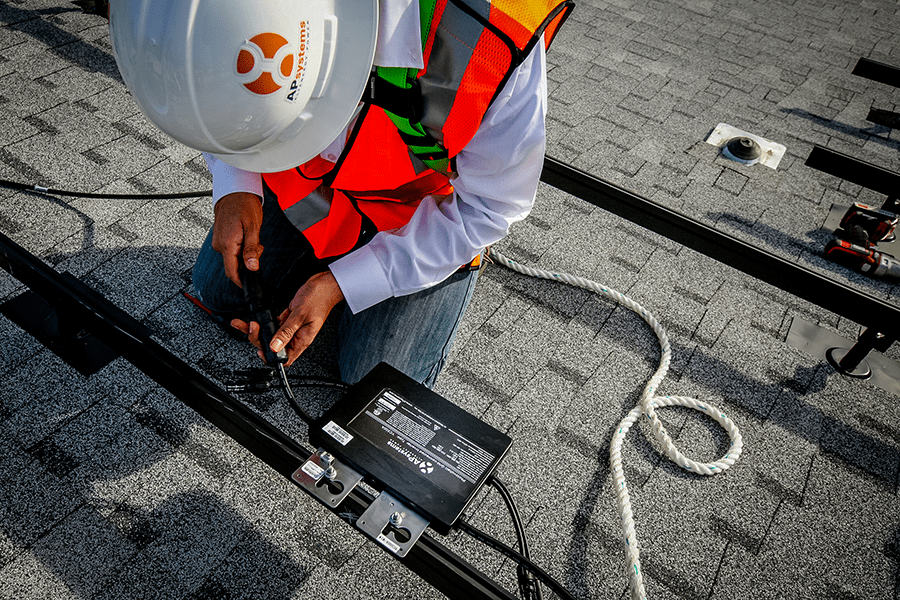

APsystems is now well recognized for its leadership in multi-module microinverters solutions bringing innovative products to market that are built to last. This is the DNA of the company and will continue to be. We have several new microinverter products planned to be launched in the coming 18 months including a new native 3-phase QUAD microinverter at the end of this year, but our ambition moving forward is also to increase our position in other Module Level Power Electronics. We have recently launched, especially in the United States, APsmart, a new Business Unit that includes advanced safety products such as a Module Level Rapid Shut-Down (MLRSD) device to meet new safety regulations on MW-scale solar projects. The APsmart MLRSD System is a SunSpec Alliance Certified device which maintains constant communication between the RSD and Transmitter, constantly monitoring voltage and current. APsmart offers state-of-the-art PV module rapid shutdown devices (RSD), ideal for any new or existing string or central inverter system, and meeting U.S. NEC 2017 690.12 Rapid Shutdown requirements.

APsystems is also working on a modular AC coupled Energy Storage System (ESS) for residential where priority, similarly to every product we manufacture, is given to high quality & reliability.

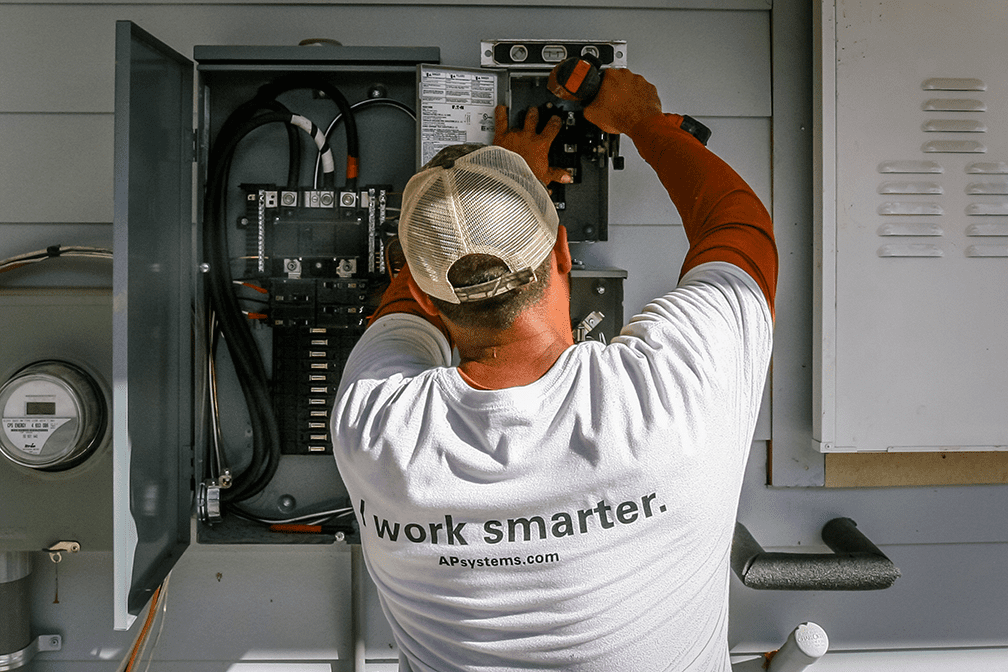

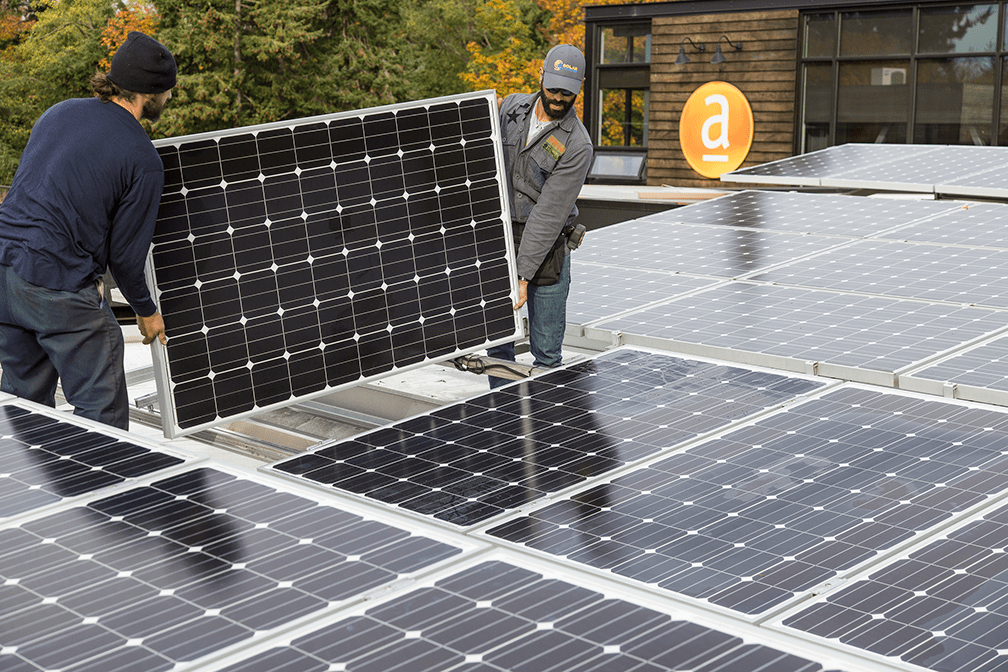

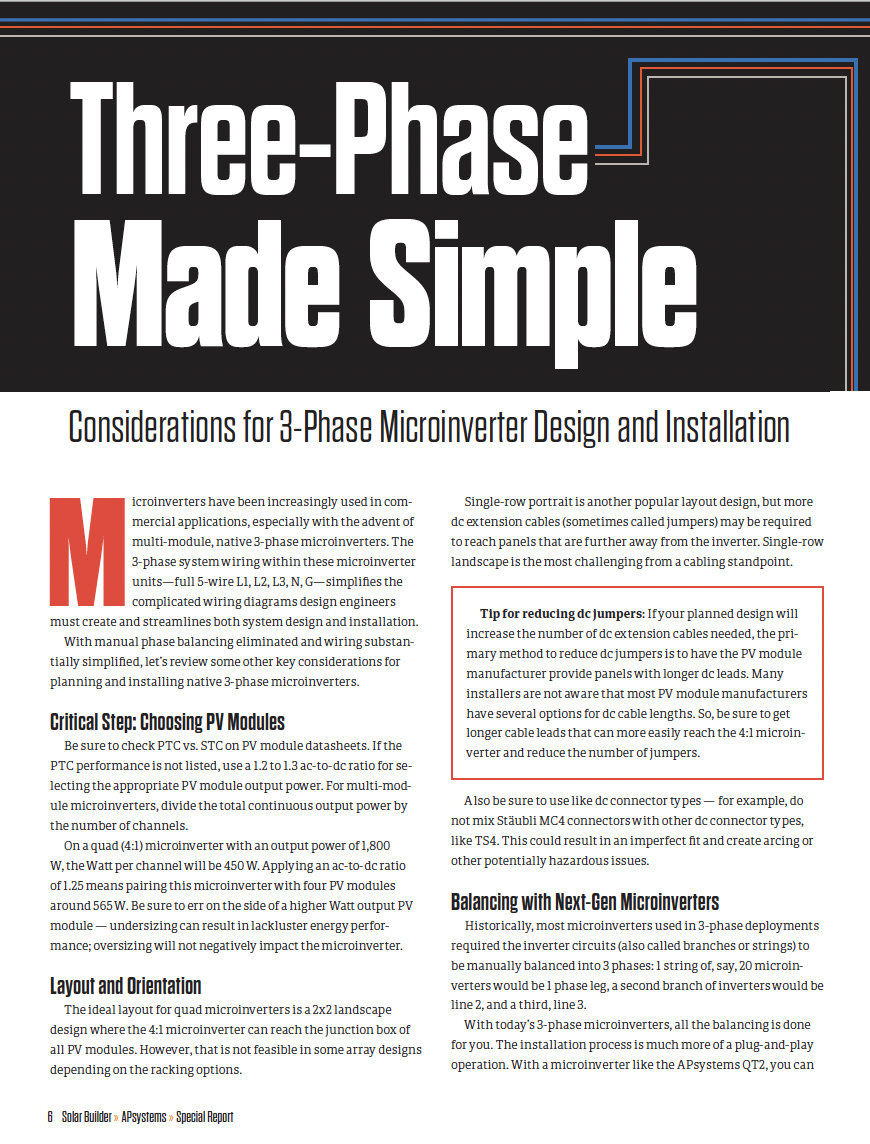

This exclusive article from APsystems was featured in the recent Special Report by Solar Builder magazine, “The Case for Microinverters in C&I Solar.” It explores the growing adoption of microinverters in commercial applications, particularly the native 3-phase microinverters that have revolutionized the industry. The article highlights the simplified wiring diagrams and streamlined installation process made possible by the 3-phase system wiring, along with key considerations for PV module selection, layout design, next-gen microinverters, racking choices, and gateway placement.

This exclusive article from APsystems was featured in the recent Special Report by Solar Builder magazine, “The Case for Microinverters in C&I Solar.” It explores the growing adoption of microinverters in commercial applications, particularly the native 3-phase microinverters that have revolutionized the industry. The article highlights the simplified wiring diagrams and streamlined installation process made possible by the 3-phase system wiring, along with key considerations for PV module selection, layout design, next-gen microinverters, racking choices, and gateway placement.