APsystems

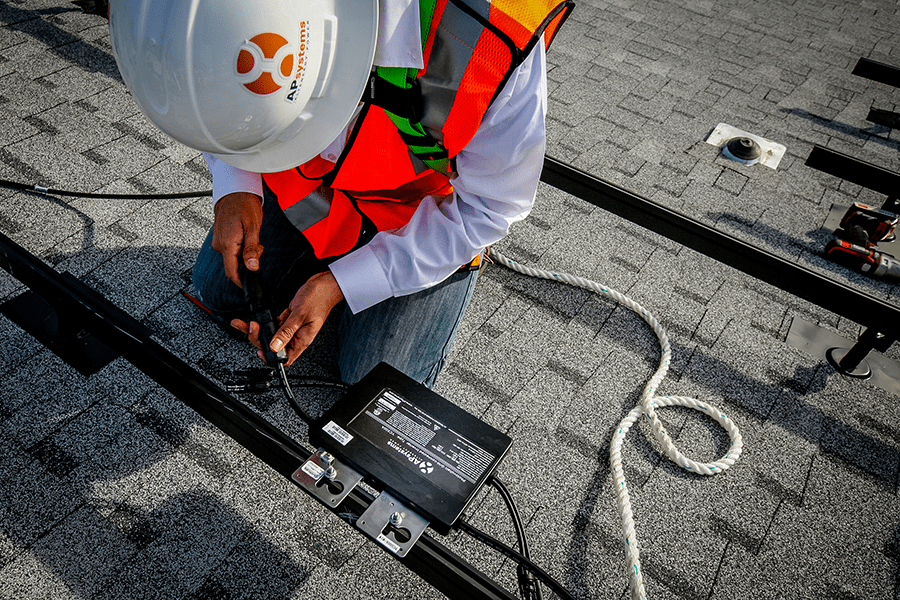

APsystems is the #1 global multi-platform MLPE solution provider, offering microinverter, energy storage and rapid shutdown devices for the solar PV industry. APsystems brands include APsmart and APstorage. Founded in Silicon Valley in 2010, APsystems encompasses 4 global business units serving customers in over 100 countries. With millions of units sold producing more than 4TWh of clean, renewable energy, APsystems continues to be a leader in the ever-growing solar MLPE segment.

News

Mark Your Calendars for These Upcoming May TradeshowsApril 18, 2024 - 4:41 pm

Mark Your Calendars for These Upcoming May TradeshowsApril 18, 2024 - 4:41 pm Innovation and Impact: Unveiling the 2023 APsystems Project Award WinnersMarch 23, 2024 - 7:30 pm

Innovation and Impact: Unveiling the 2023 APsystems Project Award WinnersMarch 23, 2024 - 7:30 pm Empowering Wellness: Dynamic Solar & Electric NW Corp’s Solar ContributionMarch 22, 2024 - 9:26 pm

Empowering Wellness: Dynamic Solar & Electric NW Corp’s Solar ContributionMarch 22, 2024 - 9:26 pm Uniting Patriotism and Power: Idahome Energy’s Flag-Roof Solar ProjectMarch 22, 2024 - 8:46 pm

Uniting Patriotism and Power: Idahome Energy’s Flag-Roof Solar ProjectMarch 22, 2024 - 8:46 pm Shining Bright: Green Box Solar Lights Up Central Valley MachineMarch 20, 2024 - 10:25 pm

Shining Bright: Green Box Solar Lights Up Central Valley MachineMarch 20, 2024 - 10:25 pm

Contact Details

At APsystems, we are committed to providing the highest quality service to our customers and partners around the world.

8627 N. Mopac Expy, Ste 150

Austin, TX 78759

United States of America

Phone:1-844-279-8600